This past summer I took a two-week intensive course on flameworking with Gianni Toso. We were working with soft glass, which is fun. However, several of my glass friends and instructors have insisted that I should be working with borosilicate glass - especially for making the stands I use for my carved leaf bowls. So, I jumped into that realm this semester by taking an independent study course in glass at The Ohio State University.

I'm sold. I will continue to play with soft glass, but I can foretell that my future work will be mostly in boro. The funny thing is that when I order borosilicate color rods from one of my suppliers, they send me stickers that are about marijuana use. I do not intend to ever make bongs or other smoking apparati. I do get a kick out of the stickers, though.

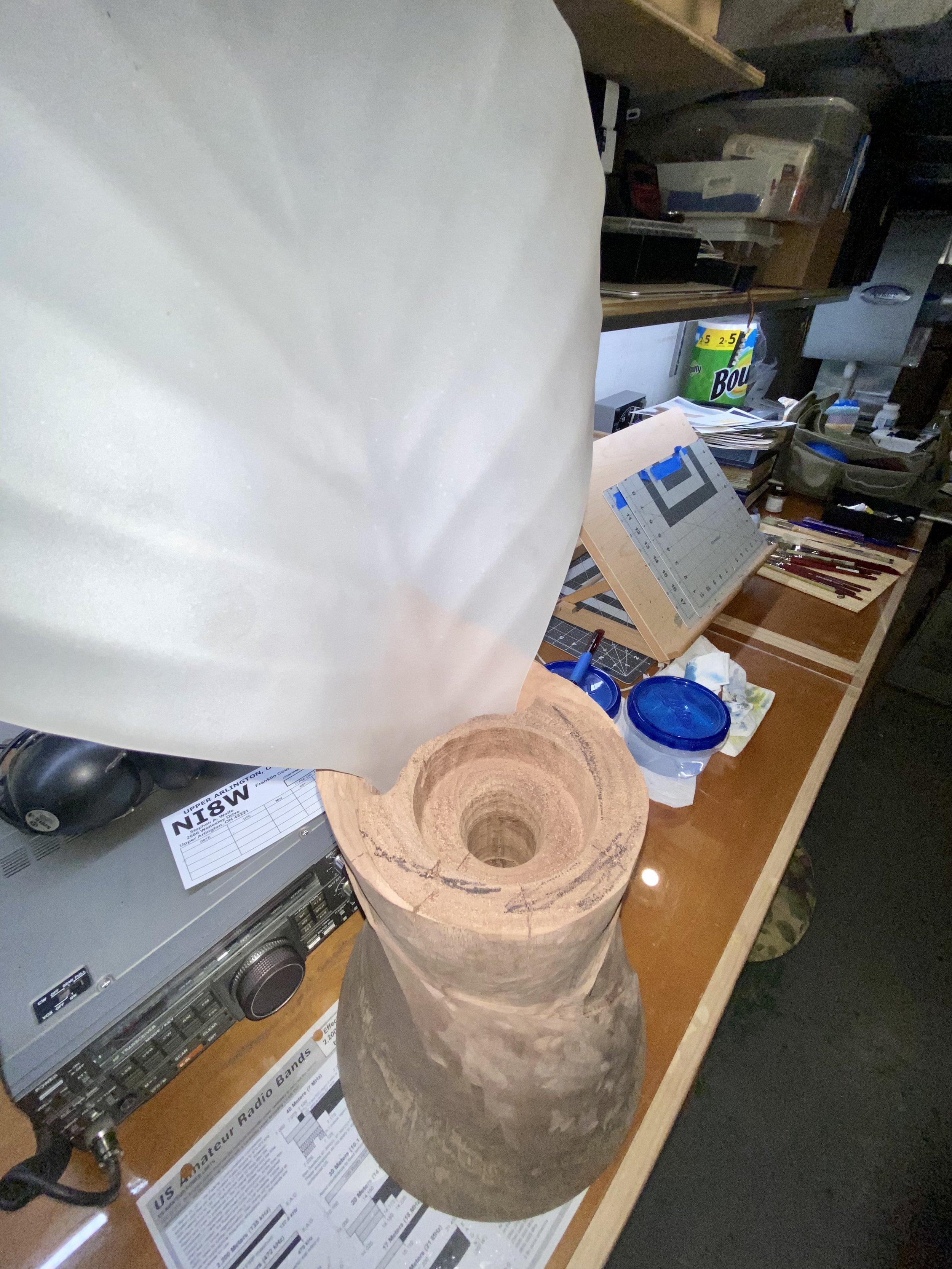

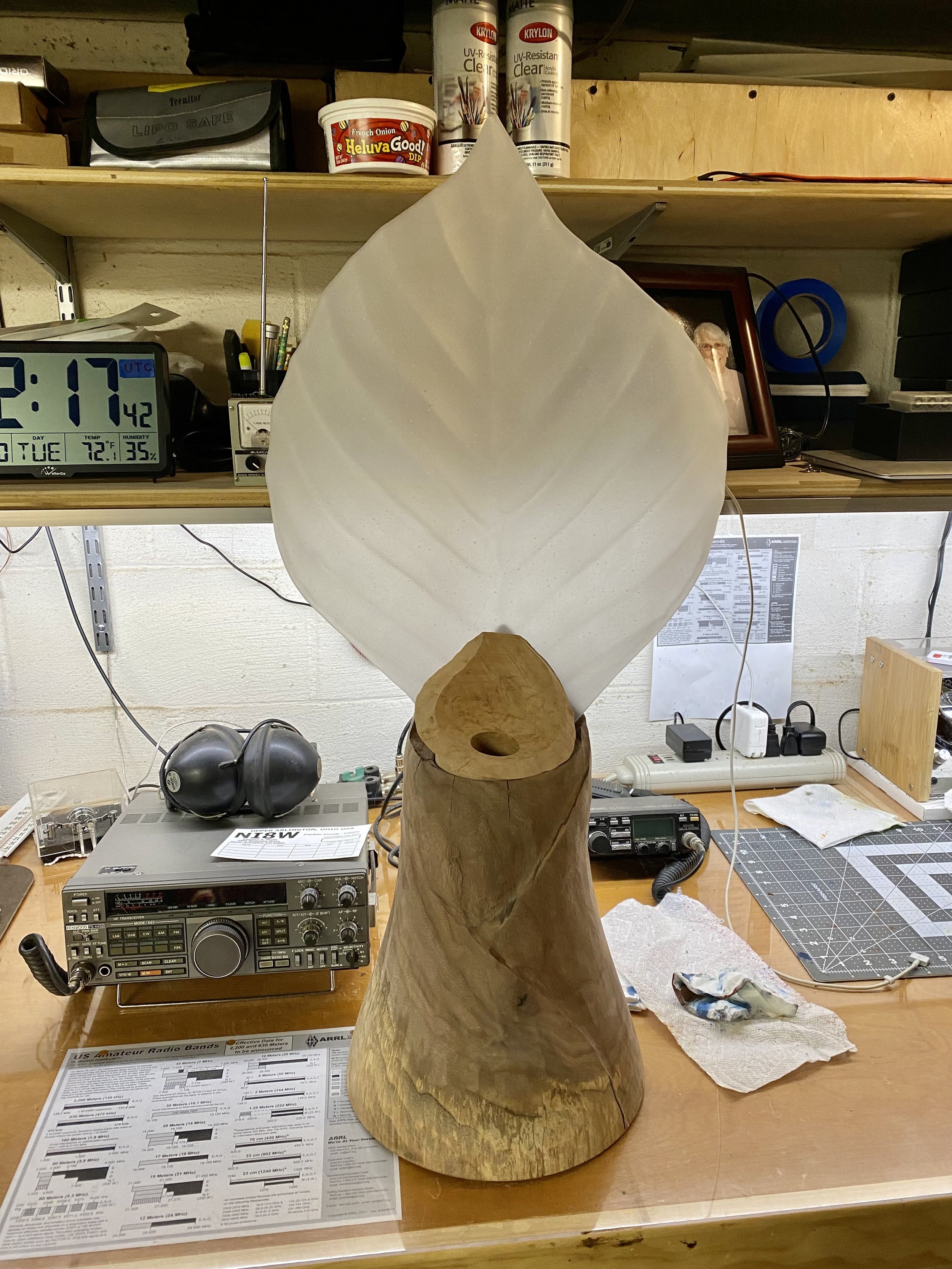

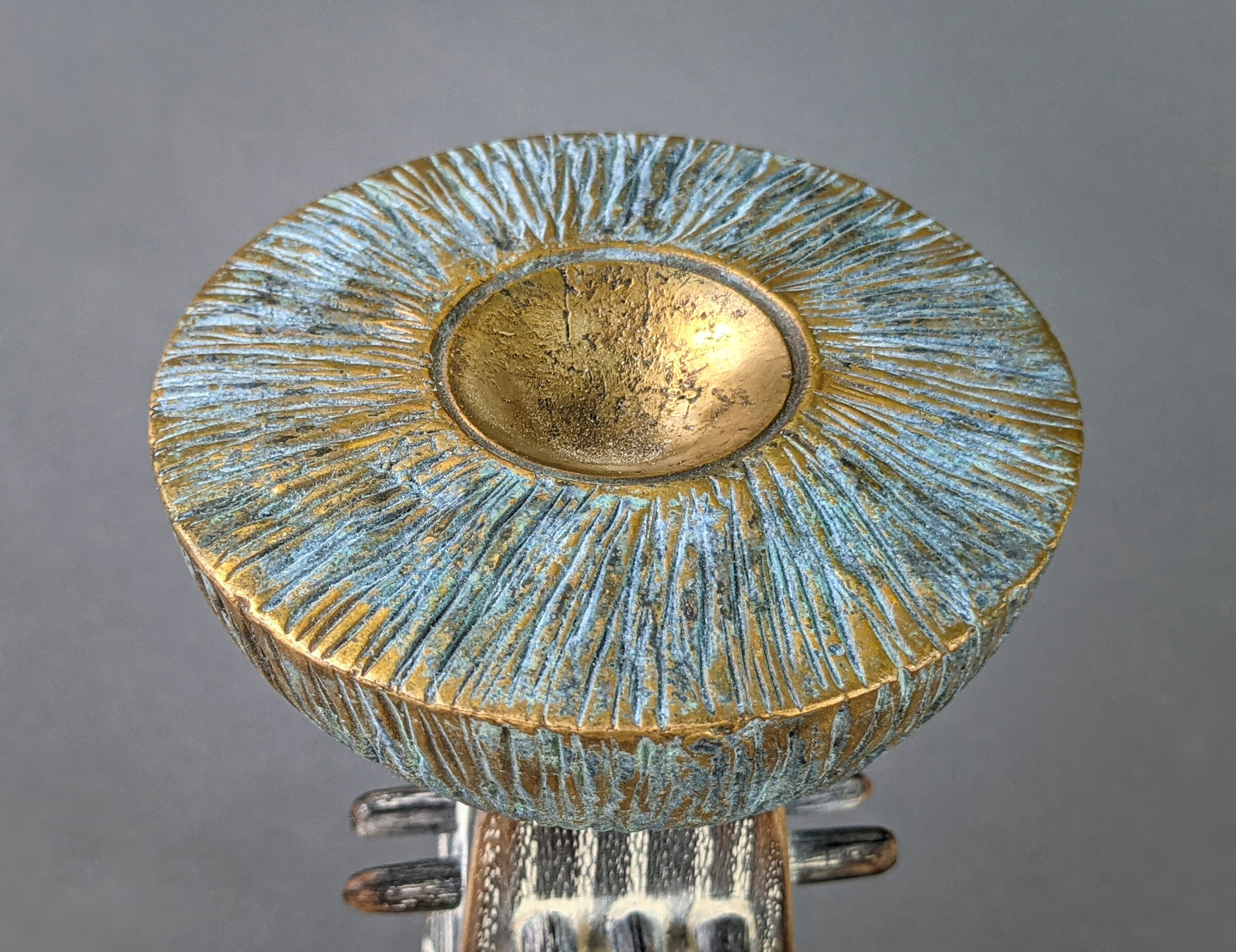

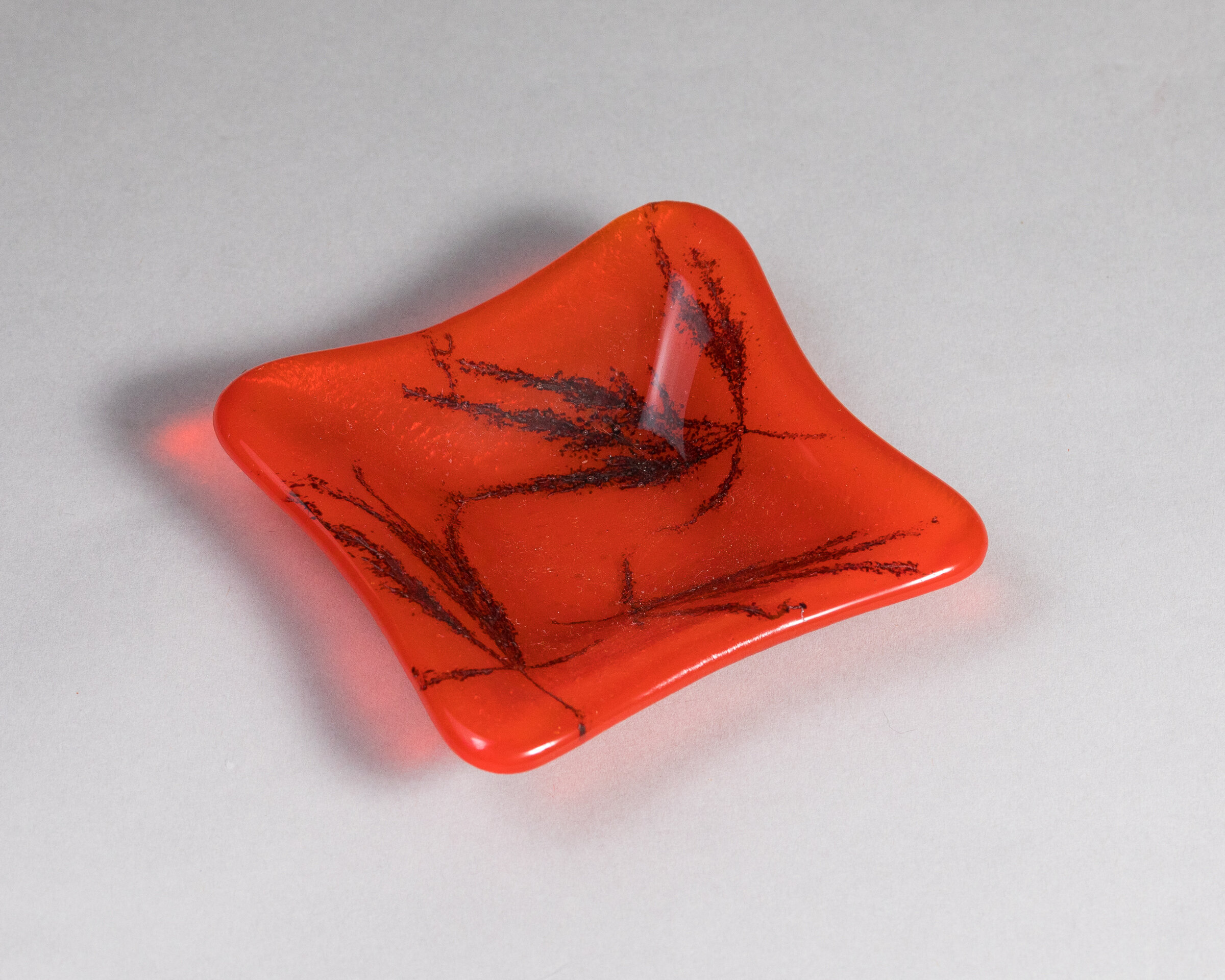

My first wood and borosilicate glass sculpture is Bole-tangle, which is 11 X 6 X 5.5 inches, and made from black walnut and Oregon myrtle. The hollow form is light-weight. I made this to look as if the glass vines were growing in and out of the vessel.

In this view, you can see where the vine emerges from the hollow form and lid.

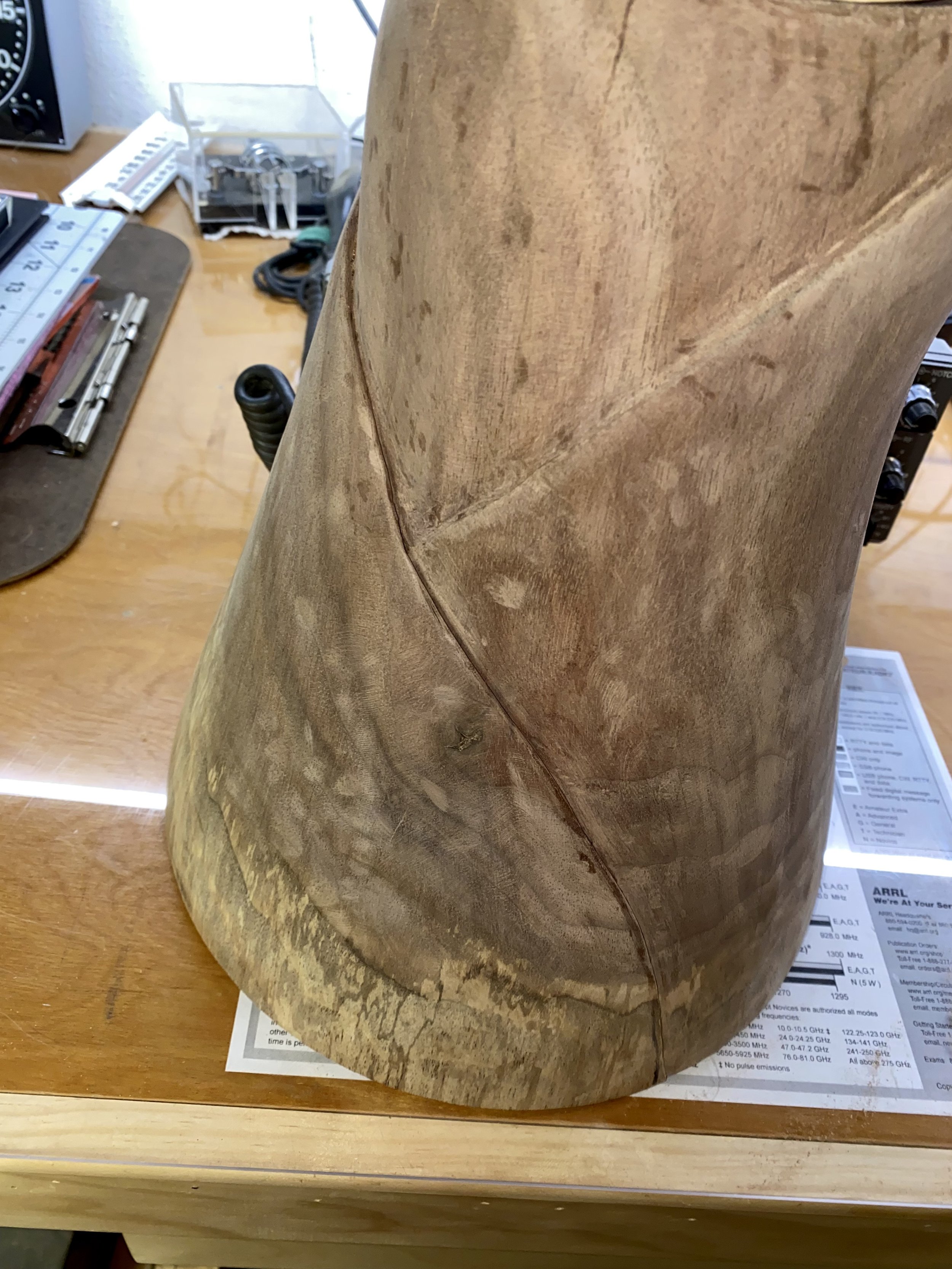

On the lower left side of the vessel, the vine appears to enter the wood.

One major thing I learned is how to repair broken borosilicate glass. It turns out that there are different kinds of connections in boro - hot seals and cold seals. A hot seal is when the glass that is connected is totally melted together. A cold seal does not have this feature and can break with just a gentle tap. So, I learned, by lots of practice, how to make hot seals.

I also found out how much I enjoy making leaves and vine-like structures.

I like the tension and motion of this piece. It has generated a bunch of ideas for future work.